4Cr13 ötvözött acél

- Shizhang Steel

- Kína

- 15-45 nap

- 500 tonna/hónap

A 4Cr13 acél kiváló minőségű martenzites rozsdamentes acél. Ez az acél jó megmunkálási teljesítménnyel rendelkezik. Hőkezelés (hűtés és temperálás) után kiváló korrózióállósággal, polírozási teljesítménnyel, nagy szilárdsággal és kopásállósággal rendelkezik, nagy terhelésnek és nagy igénybevételnek ellenálló gyártásra alkalmas. Műanyag formák, csapágyak, elektromos berendezések, műszerek, műszerek, turbinalapátok, rugók, vágószerszámok, fúvókák, szelepülékek, szelepcsapágyak, kopásálló anyagok stb. 4Cr13 rozsdamentes acél kerek rudak és lemezek

Product Name: ALLOY STEEL---4Cr13

Similar steel grades:

U.S.A | P20+S |

German | X40Cr13 |

Japan | - |

Austria | - |

Sweden | - |

China | 4Cr13 |

Chemical composition:

Standard | C | Si | Mn | S | Cr | Mo | P |

GB/T 1220-1992 | 0.35-0.45 | 0.30-0.50 | 1.40-1.60 | 0.05-0.10 | 1.80~2.0 | 0.15~0.25 | ≤0.030 |

Principal Feature:

4Cr13 steel is a high-quality martensitic stainless steel. This steel has good machining performance. After heat treatment (quenching and tempering), it has excellent corrosion resistance, polishing performance, high strength and wear resistance, and is suitable for manufacturing to withstand high loads and high Plastic molds, bearings, electrical equipment, instruments, instruments, turbine blades, springs, cutting tools, nozzles, valve seats, valve bearings, medical equipment, etc. that are wear-resistant and exposed to corrosive media.

Typical Application:

4Cr13 steel is suitable for electrical discharge and grinding processes. It is suitable for making mold cores and cavities of high-precision injection molds with high mirror surface. It has high hardness and toughness after heat treatment. It can also be used for stamping mold accessories, templates, etc., where there are requirements for clamping on the surface of the product. Jigs and molds, etc.; suitable for scenes with high temperature rust and anti-corrosion.

Civil use: can be used to make table knives and outdoor knives.

Heat Treatment:

Annealing, slow cooling at 800~900℃ or rapid cooling at about 750℃;

Quenching, oil cooling at 1050~1100℃;

Tempering, air cooling at 200~300℃.

Metallographic structure: The structure is characterized by martensite type.

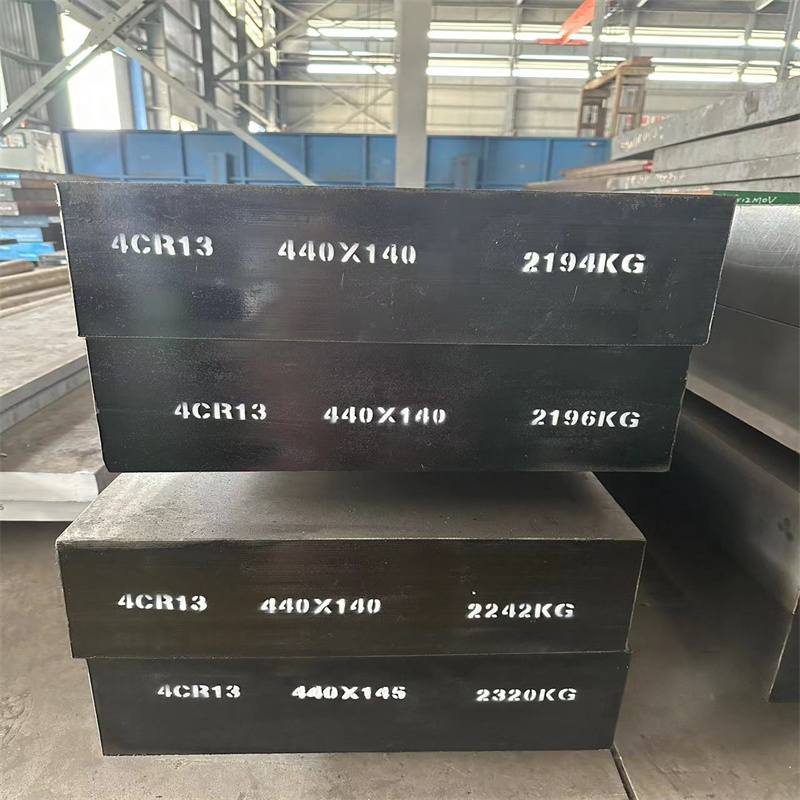

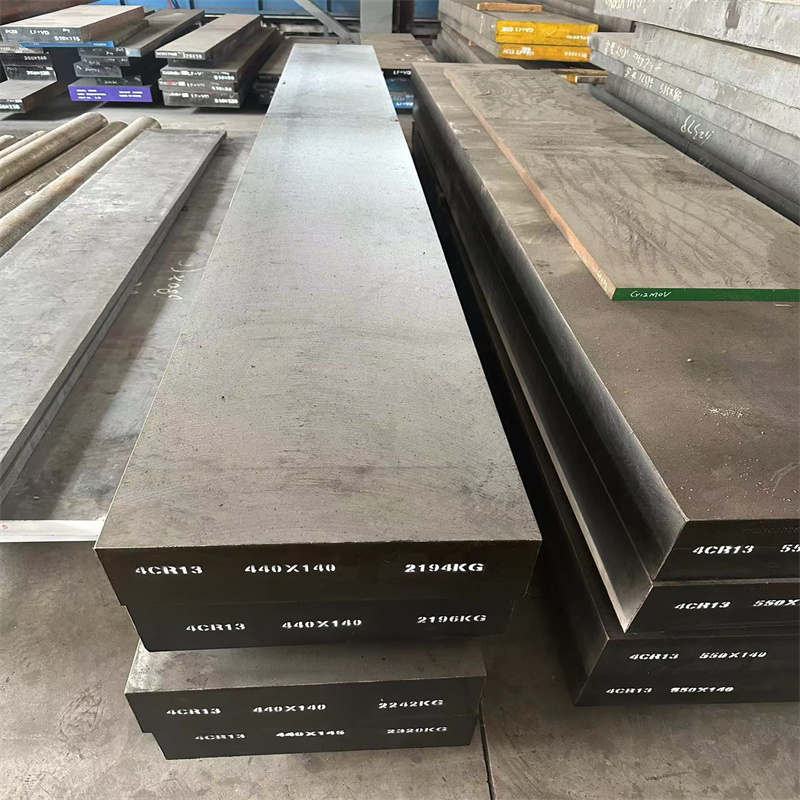

Size available:

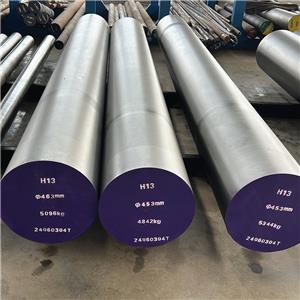

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |